Not wool, but very interesting as raw wool fleece faces similar processing challenges within Ireland.

Not so long ago, all the processes that make-up linen production – from soil to finished textile– were still alive in Ireland, especially in the northern regions. Sadly, today Irish linen is only woven and/or finished in Ireland; everything else happens abroad. Fortunately, there are still weavers and finishers whose craft has survived, and their skills are a living heritage.

A few years ago, Helen Keys and Charlie Mallon from Mallon Linen started growing flax. Today, not only are they still growing it, but they’ve managed to acquire the machinery and knowledge to process the flax fibres up to the hackling stage.

The missing link is spinning. If only we had flax spinning machinery in Ireland, we could revive our local linen production all across the value chain!

Enter Mourne Textiles, a third-generation weaving company that has a mission to restore vintage flax processing and spinning equipment to create a sustainable circular supply chain from hemp to linen for all of Ireland.

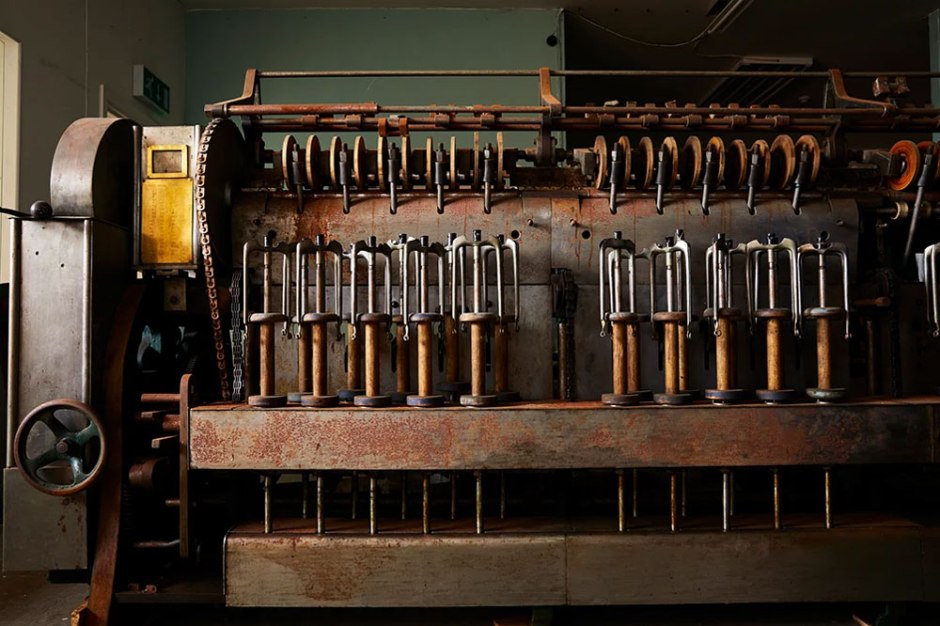

They discovered a complete set of industrial flax-spinning machines. Although old, these machines are still very relevant for processing flax and hemp fibres after they have been harvested, scutched, and heckled.

In collaboration with local farmers at Mallon Linen, and researchers at Ulster University, Mourne Textiles aims to promote sustainable fabric production here on the Island of Ireland by creating a field-to-fabric circular supply chain. Their focus is on producing environmentally friendly fabrics grown and processed locally.

The Mourne Textiles fundraiser runs through the 30th of June. To learn more and give your support, visit here – https://www.crowdfunder.co.uk/p/fibre-to-fabric